Omniful's AI Powered Returns Management System vs SAP Advanced Returns Management

İçindekiler

SAP Advanced Returns Management (ARM) Against OMS: Control Tower Fit, Integrations, and Returns Ops

TL;DR

SAP Advanced Returns Management (ARM) is SAP’s structured approach to managing returns end-to-end, with inspection results and follow-up steps tied to refund decisions.

ARM fits best as the ERP-side system of record for returns, while customer-facing initiation and physical execution typically live outside SAP.

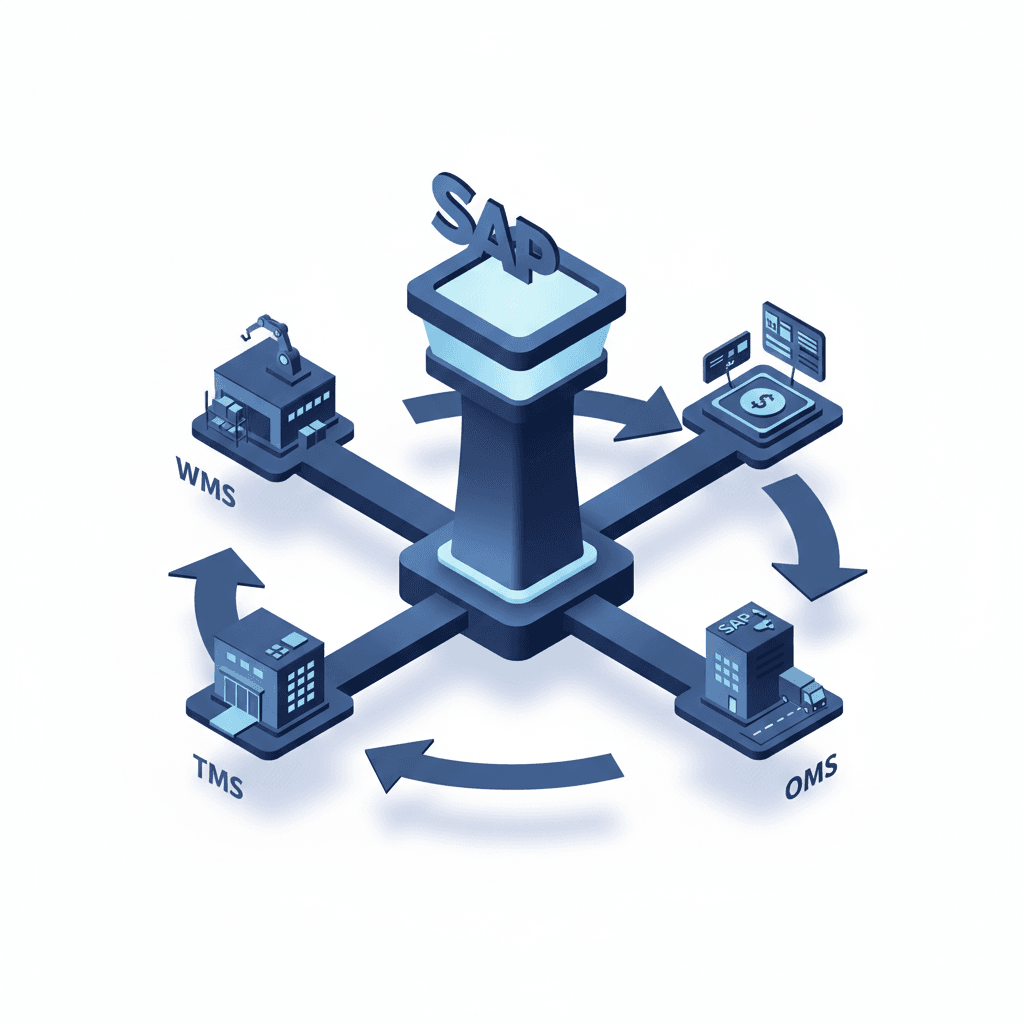

OMS vs WMS vs TMS: OMS decides and coordinates, WMS executes warehouse work, TMS executes transportation. ARM usually sits with ERP and OMS-level decisioning, not execution.

Faster refunds come from event-driven triggers such as receipt scans, inspection results, and rule-based refund release.

Successful integration depends on clean IDs, shared statuses, and low inventory latency across stores, DCs, and 3PLs.

Introduction: Returns Are a Chain of Decisions

Returns fail when teams treat them as a single action.

They are not.

A good returns setup works like a control tower. It does not do the physical work. It coordinates what happens next and keeps systems aligned.

A Simple Returns Scenario

An order is placed online.

It is fulfilled from a store and shipped via a carrier.

The customer wants to return the item and expects clarity and a quick refund.

Behind the scenes, the business must answer key questions quickly:

- What was shipped and from where?

- Where should the return go next?

- Do we refund on first scan or after inspection?

- Do we restock, refurbish, replace, or scrap?

This is where advanced returns management in SAP becomes relevant.

SAP Advanced Returns Management is designed to structure these decisions inside SAP. It supports both customer and supplier returns and links inspection outcomes to follow-up actions.

ARM is one part of the control tower. Clear boundaries with OMS, WMS, and TMS are still required.

What an OMS Controls in the Supply Chain

Before placing SAP ARM, it helps to anchor the basics.

When teams ask what order management in supply chain means, the practical answer is simple.

An OMS is the decision layer for the order lifecycle in SCM.

Order Capture and Normalisation

Orders arrive from multiple channels.

The OMS standardises:

- Order structure

- Line items

- Addresses and customer data

This creates one shared truth for downstream systems.

Validation

The OMS enforces rules such as:

- Address validity

- Payment confirmation

- Return eligibility windows

- Policy checks

Bad validation leads to failed deliveries and avoidable returns.

Allocation and Inventory Availability

Allocation decides which inventory serves the order.

This is tied to inventory availability and reservation logic across nodes.

Fulfilment Node Selection

The OMS decides where fulfilment happens.

Possible nodes include:

- Warehouses

- Stores

- 3PLs

This decision directly impacts returns routing later.

Promise Date Logic

The OMS calculates the promise date.

This commitment drives customer trust and later refund expectations.

ATP and Backorders

ATP stands for Available to Promise.

It represents inventory that can be committed, not just what appears on hand.

Backorders occur when demand exceeds supply and often lead to cancellations or exchanges.

Orchestration and Exception Workflows

Orchestration coordinates steps across systems.

Exception workflows answer the “what now?” questions when reality breaks the ideal flow.

SAP ARM typically sits inside ERP returns processing and document flow. It does not replace a full omnichannel OMS.

What an OMS Does Not Control

A control tower only works when boundaries are clear.

An OMS usually does not control execution.

Warehouse Execution Details

Warehouse execution includes:

- Bin placement

- Scan paths

- Putaway

- Picking waves

- Packing stations

These belong to a WMS.

Transportation Execution

Transportation execution includes:

- Carrier booking

- Driver assignment

- Route optimisation

- Tracking events

- Proof of delivery

These belong to a TMS or carrier systems.

Physical Inspection Work

Systems can request and record inspections.

People and warehouse processes perform the actual inspection.

This applies to SAP ARM as well.

ARM can drive follow-up decisions using inspection results, but it relies on WMS and TMS to execute and confirm physical steps.

OMS vs WMS vs TMS

Keeping this distinction clear avoids integration mistakes.

OMS: Decides and Coordinates

Examples:

- Fulfil from Store 21 to meet the promise date

- Refund after inspection grade equals A

WMS: Executes Warehouse Work

Examples:

- Receive return at dock

- Inspect and grade

- Restock to the correct bin

TMS: Executes Transportation Work

Examples:

- Schedule pickup

- Print label

- Track movement and capture proof

In SAP environments, SAP can span multiple roles.

ARM itself focuses on returns structure, inspection linkage, follow-up activities, and refund handling. It does not handle last-mile pickup execution or bin-level warehouse tasks.

Key Workflows Where OMS Matters Most

Returns move faster when the forward flow is clean.

These workflows are the biggest levers.

ATP (Available to Promise)

Accurate ATP reduces false promises.

Fewer false promises lead to fewer cancellations and fewer frustrated returns.

Promise Date Discipline

Promise date discipline reduces returns caused by late delivery expectations.

It also sets expectations for refund timing.

Backorders

Backorders complicate exchanges.

If replacement stock is unavailable, customers need clear options.

Split Shipments

Split shipments are normal in omnichannel.

Returns must support partial returns by shipment, not only by order.

Cancellations and Edits

Address changes, cancellations, and item swaps must be controlled.

Poor handling turns them into avoidable returns.

Returns Initiation

Returns initiation is usually customer-facing.

Many teams initiate returns outside SAP, then create structured return documents inside SAP for control and finance alignment.

SAP ARM uses a returns order structure that captures:

- Returned material and quantity

- Batch or serial context

- Return reason

- Inspection key

- Follow-up action such as credit or replacement

Common Mistakes Teams Make

These mistakes appear in most returns programmes.

Using OMS or ERP Like a WMS

Teams manage physical receiving and bin logic in OMS or ERP screens.

This creates manual work and delays.

Treating SAP ARM as the Customer Returns Portal

ARM is strong for structured processing and follow-ups.

It is not always ideal for customer self-service initiation.

Forcing it into that role reduces adoption and increases support load.

Missing Exception Management

Returns are exception-heavy.

Examples include:

- Wrong item in box

- Missing accessories

- Damage in transit

- Partial returns

ARM supports structured follow-ups, but teams still need a clear operational exception playbook.

Ignoring Inventory Latency

Inventory latency is the delay between physical reality and system updates.

Latency slows refunds and exchanges.

Misaligned Refund Triggers

If policy says refund on first scan, but systems wait for inspection, customers feel the gap.

ARM can tie refund release to processing steps, but triggers must match policy.

What to Look for When Choosing an OMS

Even with SAP ARM, an OMS strategy is still required.

Especially in omnichannel environments.

Capabilities Checklist

Order Capture and Normalisation

- Multi-channel ingestion

- Clean IDs and line-item mapping

Allocation and Node Selection

- Inventory visibility across nodes

- Rule-based fulfilment selection

ATP and Promise Date

- ATP that accounts for reservations and latency

- Promise logic aligned to real SLAs

Returns Touchpoints

- Return initiation capture

- Status visibility for customers and agents

- Clear linkage from return request to refund

Exception Workflows

- Rule-based handling

- Audit trails for decisions

Integration Readiness With SAP ARM

Key questions to ask:

- Can the OMS trigger SAP return documents cleanly?

- Can return reasons and inspection context be passed reliably?

- Can inspection results flow back to orchestration layers?

- Can refund and credit memo status flow back to customer views?

ARM is designed around structured returns processing. Integrations should respect this structure, not bypass it.

Reporting and Analytics

Returns operations are a metrics game.

Reporting should answer:

- How long does each return stage take?

- Where do returns stall?

- What is refund SLA by channel and node?

- How often do we choose replacement vs credit?

Control Tower Cheat Sheet

Controls

- Order capture and validation

- Allocation, ATP, and inventory rules

- Fulfilment node selection

- Promise date policy

- Refund vs replacement decisioning

- Inspection-driven disposition logic

Coordinates

- Warehouse receiving and inspection via WMS

- Reverse pickup and tracking via TMS or carriers

- Finance actions such as credit memo creation

Doesn’t Do

- Bin-level warehouse execution

- Carrier routing and driver assignment

- Physical QC work

Five Metrics to Watch

- Refund SLA from initiation to completion

- First scan to refund time

- Inventory latency from receipt to availability

- Return-to-disposition cycle time

- Replacement conversion rate

FAQ

What is SAP Advanced Returns Management in simple terms?

It is SAP’s structured approach to processing returns, linking inspection results and follow-up actions to refund outcomes.

Where does SAP ARM fit in returns operations?

Most often as the ERP-side control point for return documents, inspection-driven decisions, and refund processing.

How does SAP ARM handle refunds?

Refund release in the returns process can generate credit memos or trigger replacements, depending on configuration.

What is a logistical follow-up activity in SAP returns?

It is the next configured step after a return, such as repair, replacement, or other follow-up options.

OMS vs WMS vs TMS: what’s the difference?

OMS decides and coordinates. WMS executes warehouse tasks. TMS executes transportation tasks.

How do you integrate SAP ARM with an OMS?

Align IDs and statuses, send structured return initiation into SAP, and publish receipt, inspection, and refund outcomes back to the OMS.

What causes slow refunds even with ARM?

Inventory latency, missing exception workflows, and misaligned refund triggers.

Does SAP ARM replace a returns portal?

Not always. Many teams use a portal for initiation and SAP ARM for structured processing and finance alignment.

Conclusion

SAP Advanced Returns Management works best when treated as part of the control tower.

It structures returns, links inspection outcomes to follow-up decisions, and ties refund release to financial documents such as credit memos or replacements.

But ARM is not the whole tower.

The OMS still controls order capture, allocation, ATP, promise dates, and omnichannel orchestration. The WMS and TMS still execute physical work.

A practical next step is to map one real returns journey end to end. Identify trusted events such as scans, receipts, and inspection results. Then assign ownership for decisions and execution.

Some teams add a lighter orchestration layer in front of ERP returns. Platforms like Omniful can play that role, but the evaluation should remain vendor-neutral.

Clarity first. Clean integration second. Predictable refunds follow.