Table of Contents

Inventory Discrepancy Management

Overview of the Omniful WMS Inventory Discrepancy workflow for managing Lost and Extra Found items across location-based hubs.

Version: 1.0

Owner: Omniful Product Team

Summary

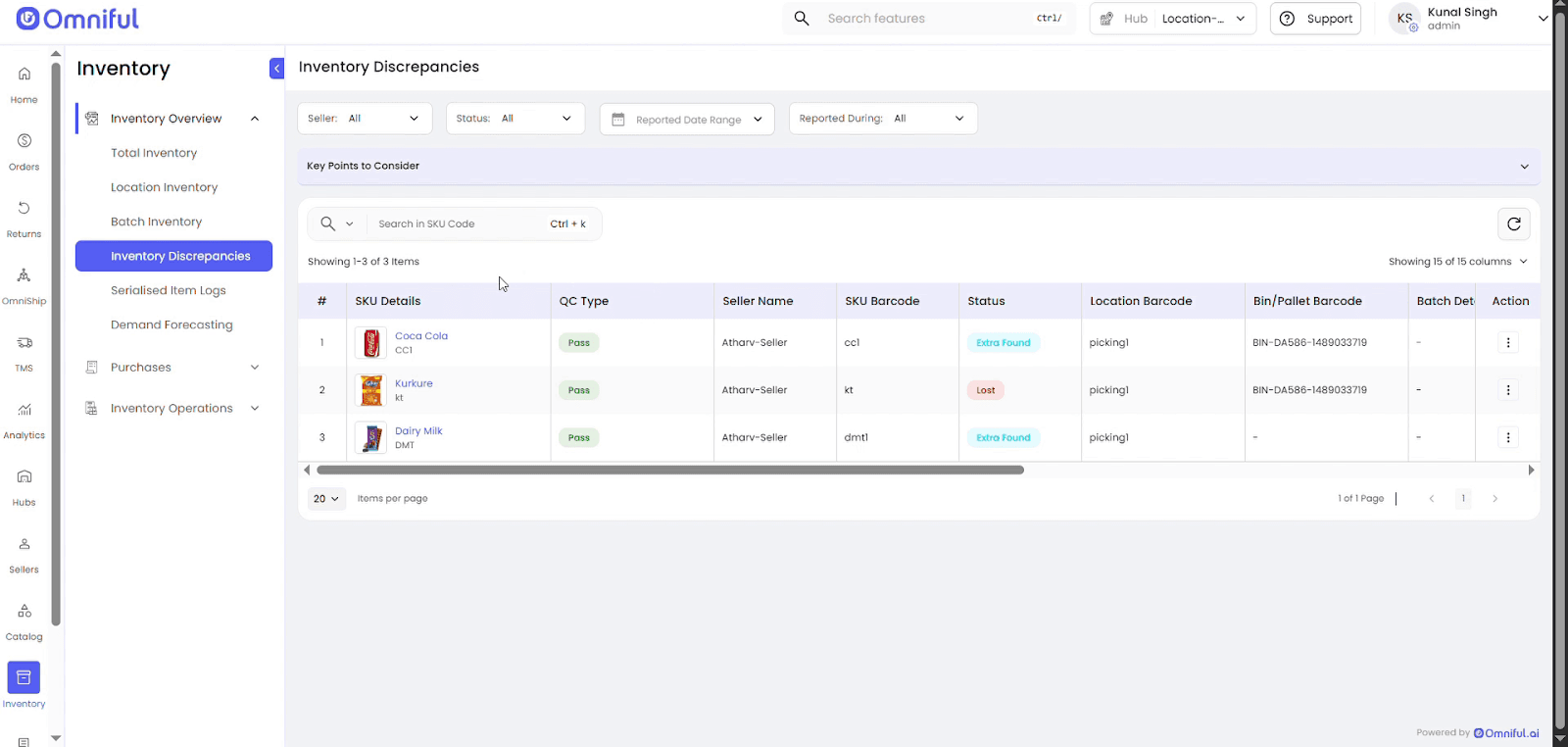

Omniful WMS provides a dedicated Inventory Discrepancy section under Inventory Overview to manage items marked as Lost or Extra Found during picking and cycle count.

Key Features

- Track and reconcile SKUs missing from their expected locations (Lost) or found unexpectedly at any location (Extra Found).

- Filter discrepancies by Seller, Status (Lost/Extra Found), Reported Date Range, and Operation (Picking/Cycle Count).

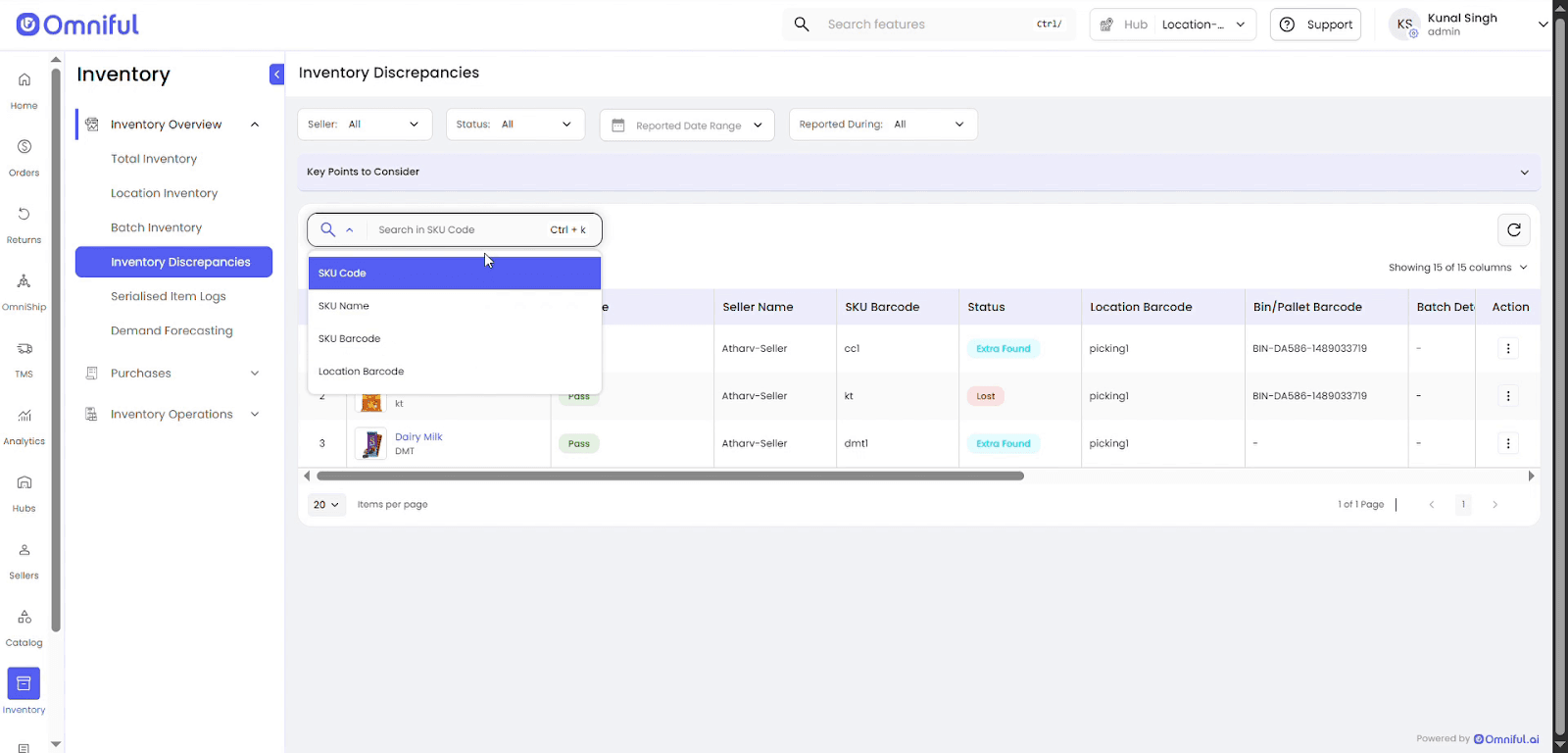

- Search discrepant inventory by SKU Code/Name/Barcode or Location Barcode.

- Provide governance via role-based permission to mark items Permanently Lost.

- Track Lost/Extra Found pass/fail quantities on Total Inventory for full visibility.

Why It Matters

Discrepancies cause fulfillment delays and stock inaccuracy. The workflow ensures real-time tracking, governed reconciliation, and accurate on-hand inventory across location-controlled hubs.

How It Works

-

Navigate to Inventory → Inventory Overview → Inventory Discrepancy to view all discrepant SKUs with fields like:

- QC

- Seller

- SKU/Barcode

- Status

- Location

- Batch

- Discrepancy Qty

- Pending Qty

- Reported During

- Reporter

- Found-on timestamps

-

Use Search and Filters to narrow by SKU/Location, Status (Lost/Extra Found), Seller, Date Range, and Operation (Picking / Cycle Count).

-

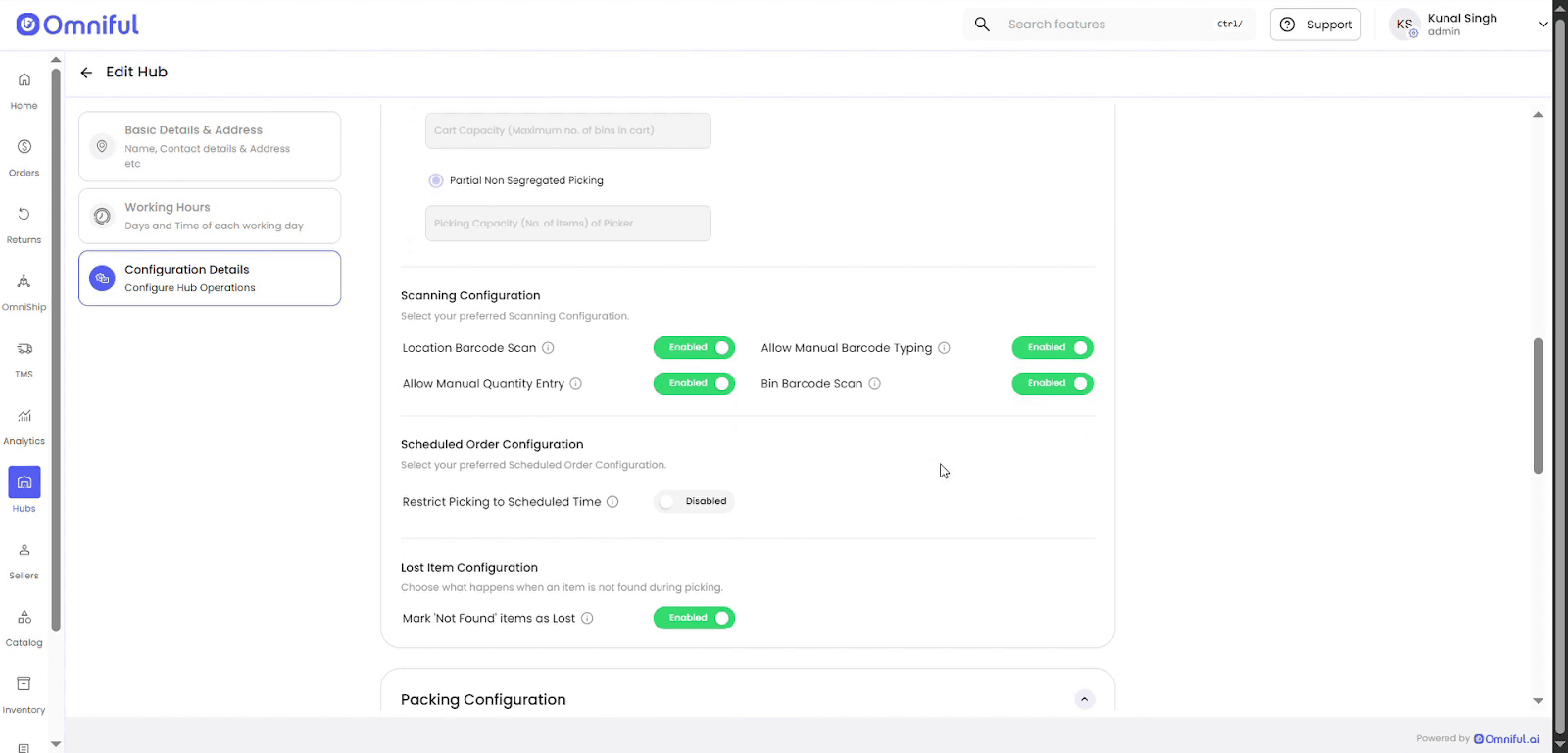

Configure Lost Item behavior for Picking:

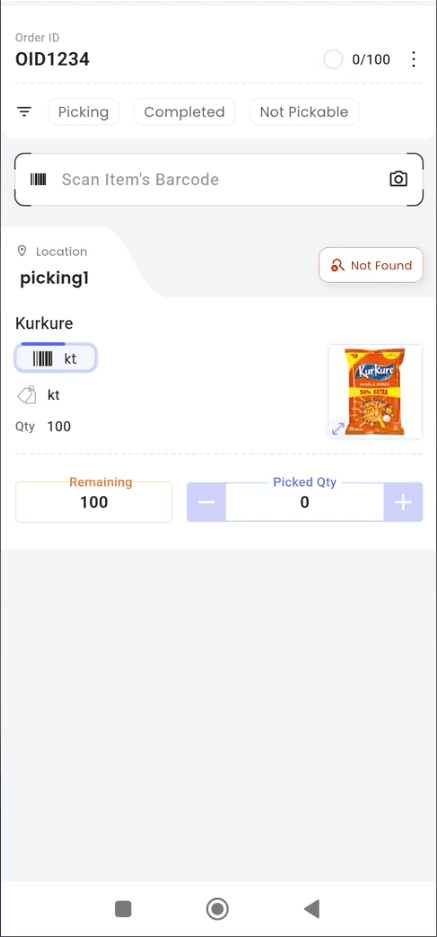

Hub → Hub Setup → Hub Overview → Picking Configuration → Lost Item Configuration (Enable/Disable).- When Enabled, pickers can mark Not Found; quantities move into Lost inventory.

- When Disabled, normal picking flow applies with reason configurations.

-

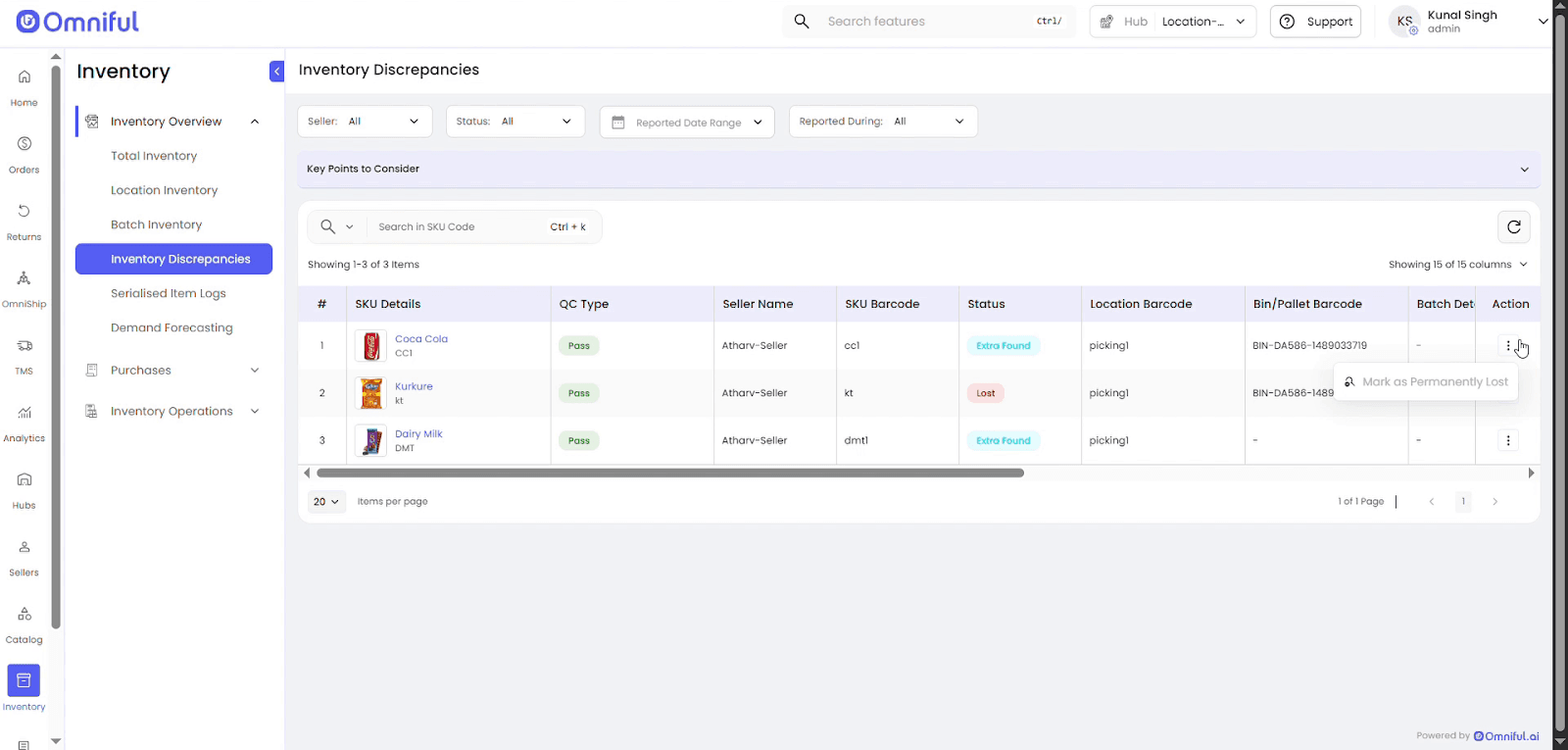

Mark Lost items Permanently Lost (admin permission).

- Quantity deducts from Lost and On-hand Inventory.

- Discrepancy entry disappears.

- Barcodes of serialized SKUs marked permanently lost cannot be recreated.

Functionalities

Technical / Configuration Notes

- Applies only to location-based inventory hubs (not hub-based).

- Discrepancy Quantity = Expected qty − Actual qty at the event; remains fixed as original log.

- Pending Quantity = remaining unreconciled amount (reaches 0 when resolved).

- Total Inventory adds columns:

- Lost Qty (Passed/Failed)

- Extra Found Qty (Passed/Failed)

- Lost items are excluded from Total Items in Location Inventory.

- When Lost Item Configuration is enabled, picker can only mark “Not Found.”

- When disabled, standard reason configurations appear.

- Cycle Count automatically moves missing items to Lost and unexpected ones to Extra Found.

Impacted Modules / Users

- WMS → Inventory Overview → Inventory Discrepancy

- Total Inventory (with added visibility columns)

- Hub Ops App (Picking flow)

- Admin Role (permission to mark Permanently Lost)

Migration / Configuration Steps

- Navigate to:

Hub → Hub Setup → Hub Overview → Picking Configuration - Enable Lost Item Configuration per hub.

- Permission for Mark Permanently Lost assigned to Admins by default.

- Communicate behavioral changes to picking teams.

Known Limitations / Rollback Guidance

- Serialized SKUs cannot be marked as Extra Found (barcode-specific reconciliation).

- Batch SKUs reconcile within the same batch.

- Non-serialized SKUs reconcile on FIFO basis unless found in original location.

- If any part of a SKU’s quantity is marked Not Found, the entire quantity is moved to Lost Qty.

- Disabling Lost Item Configuration reverts to the standard picking flow.