Table of Contents

Re-Consolidation — WMS

Corrects misplaced items during partial non-segregated picking in warehouses, ensuring accurate packing through reconsolidation workflows in the Hub Ops app.

Version: v1.0

Owner: Omniful Product Team

Summary

In partial non-segregated picking, a consolidation step is required. Even when items are correctly scanned through the PDA and assigned to bins, warehouse operators may sometimes place them in the wrong consolidation bin.

This leads to packing discrepancies:

- Scenario 1: A packer receives a bin containing extra items from another order.

- Scenario 2: Another packer gets an order with missing items because some were placed in a different bin.

Re-consolidation resolves these mismatches by identifying and correcting items placed in incorrect bins during consolidation. It supports both serialized and non-serialized items, ensuring that:

- Missing items are recovered for their correct orders.

- Extra items are returned to their rightful orders.

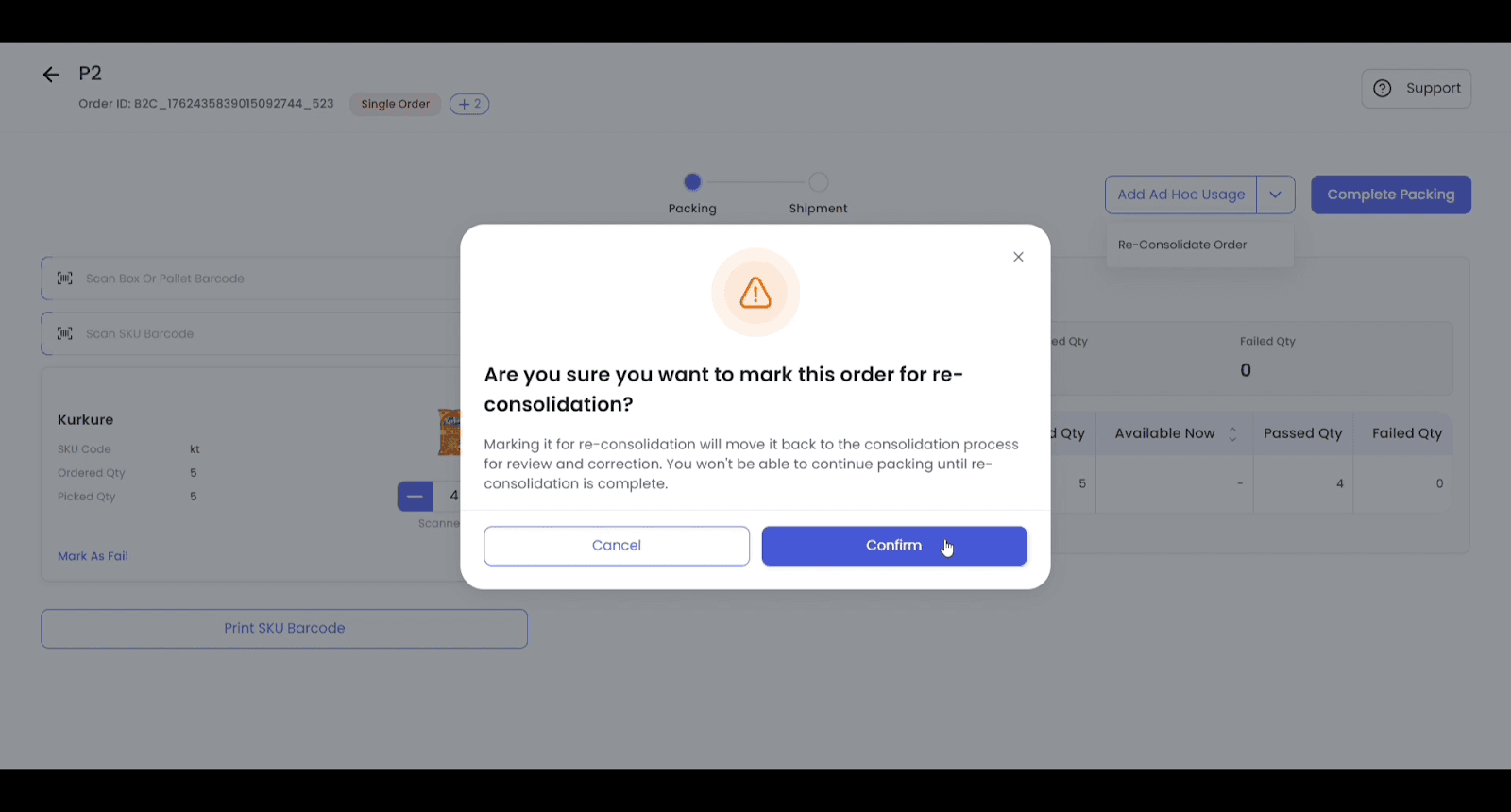

Packers can mark an order for re-consolidation directly from the packing screen when discrepancies are detected. The Hub Ops app then guides the user through item replacement, verification, and correction.

How it works

Case 1 — Missing items found during packing

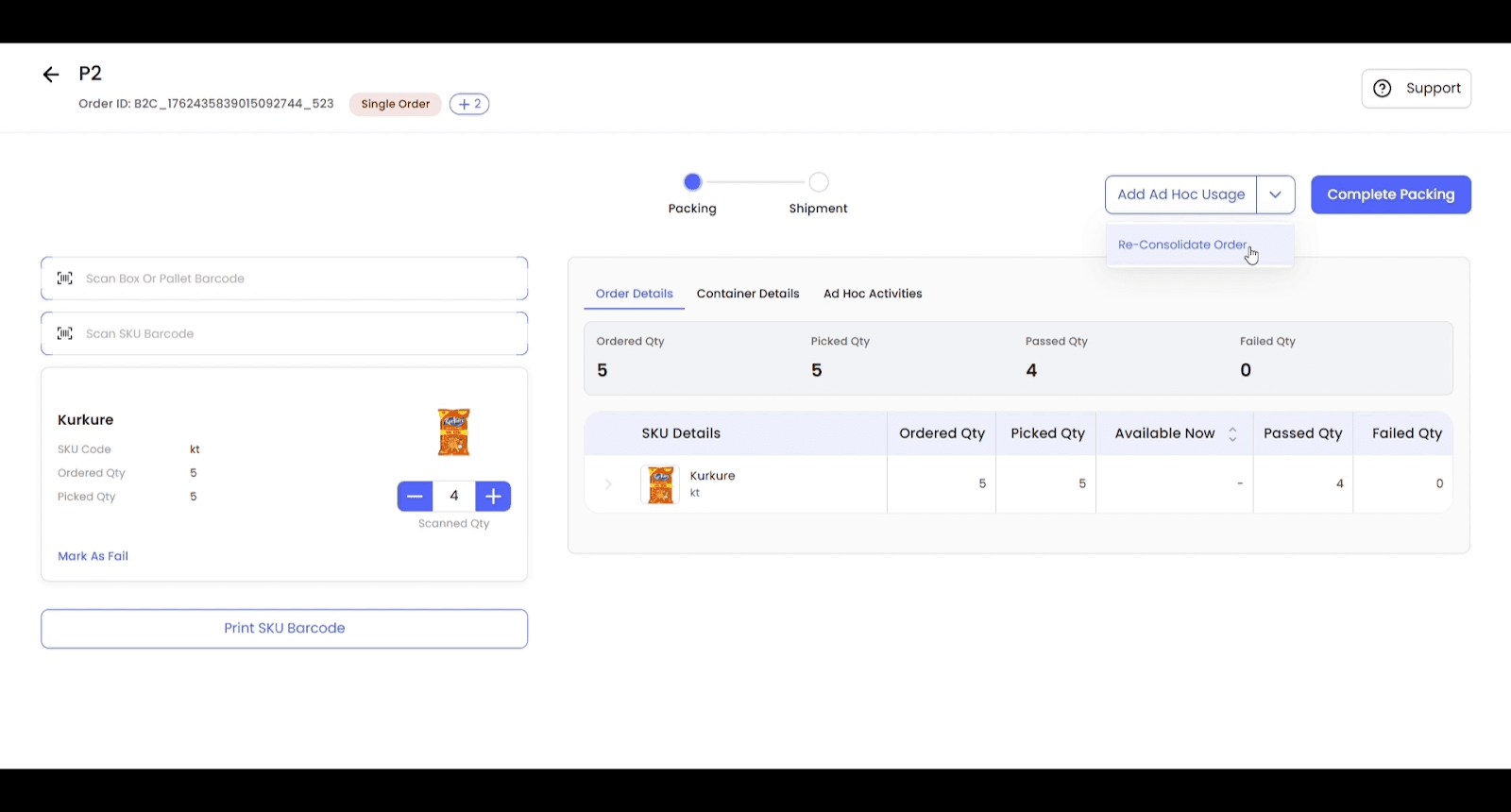

- Packer scans items; scanned quantity is less than picked quantity (shortage detected).

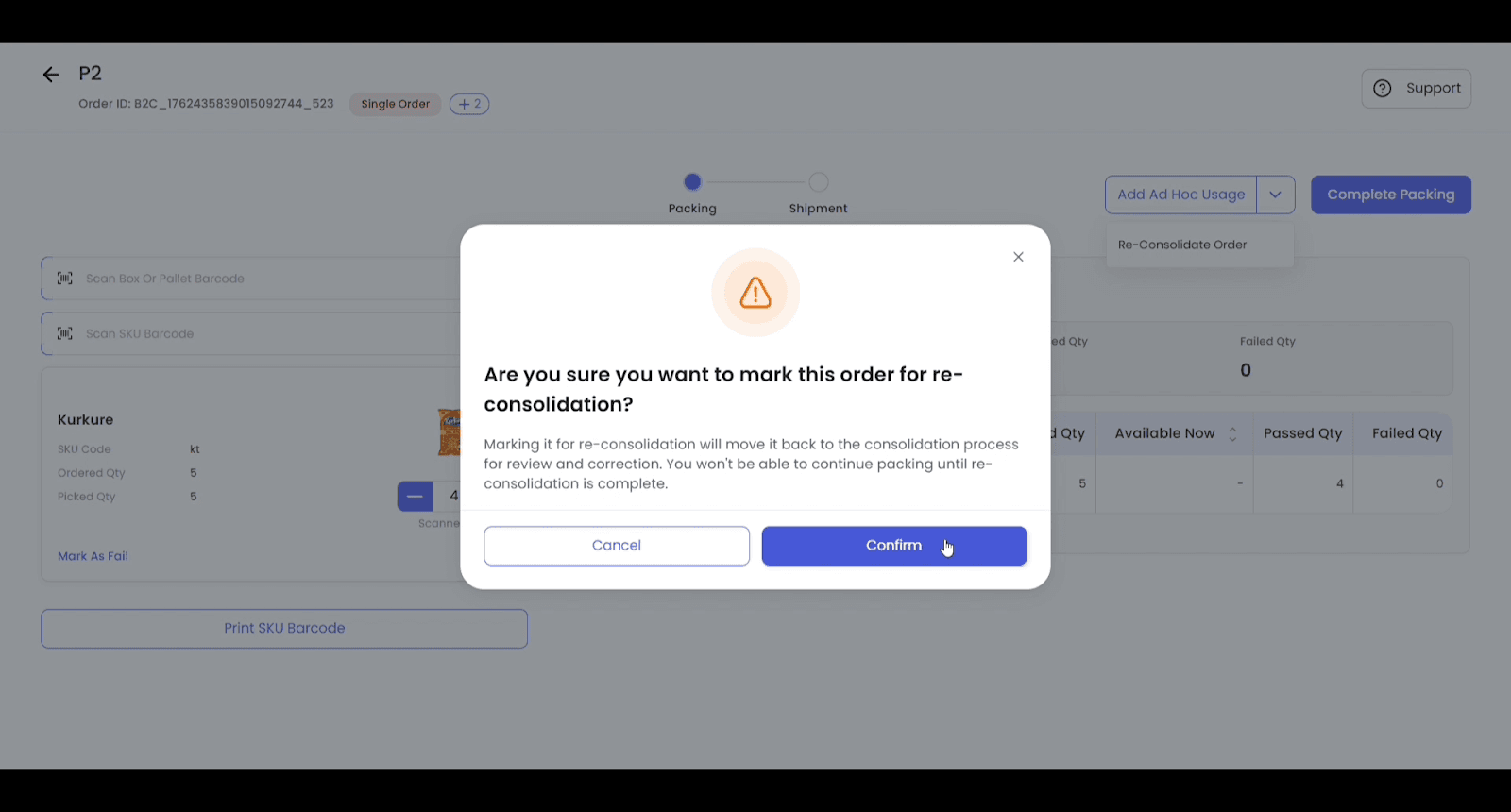

- From the CTA dropdown, select "Re-consolidate Order" and confirm. The order goes back to consolidation for review.

- If already flagged by another user, the packer is notified and can move the order to the re-consolidation queue.

Case 2 — Extra items found during packing

A) Serialized item

-

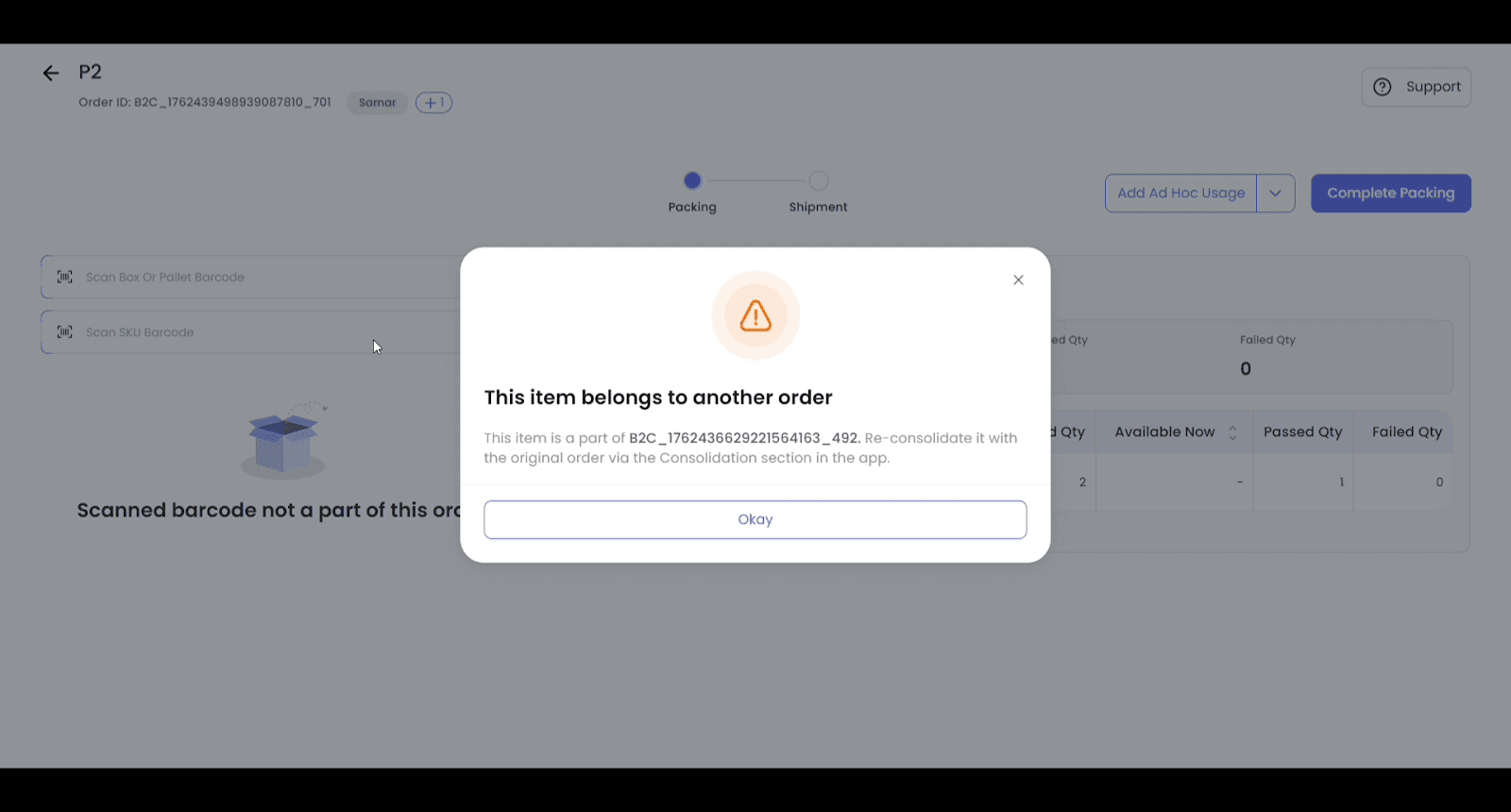

Scanning a serialized item not belonging to the order shows a modal stating "the item belongs to another order".

-

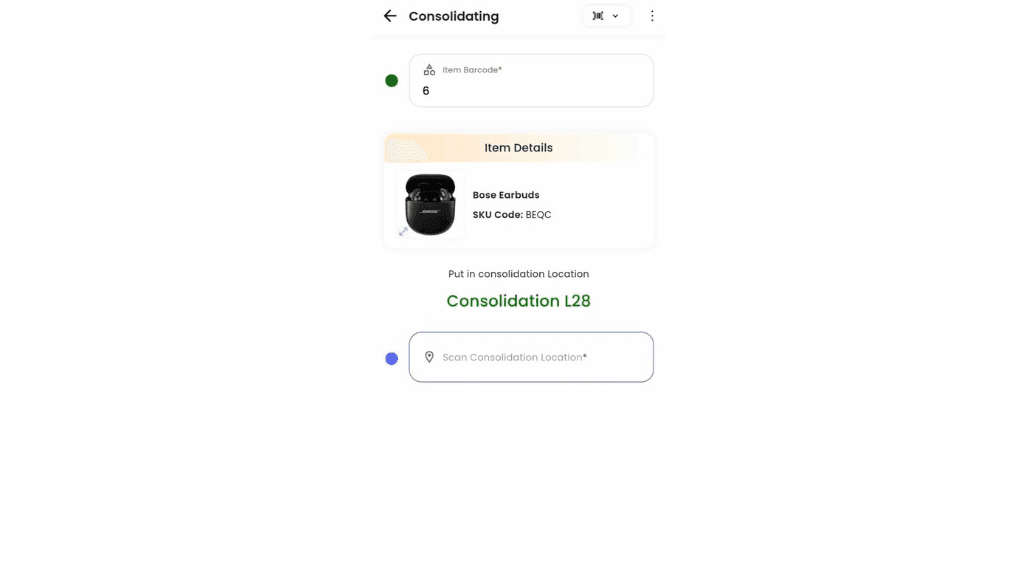

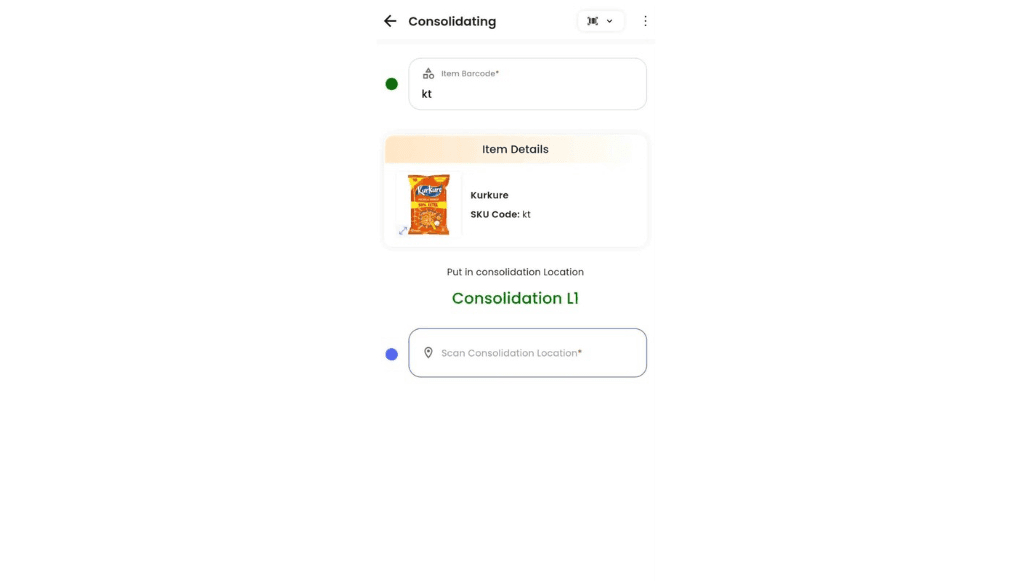

The packer can raise the issue with the floor manager or take the extra item to the consolidation area and scan in the Hub Ops app in Consolidation → Item Consolidation. The app guides based on the original order’s current state.

Consolidation screen scenarios based on the state of the original order:

-

Original order in Consolidation: Place item in the correct consolidation bin; it is re-added to the original order automatically.

-

Original order is Consolidated / Ready to Pack / In Packing: System asks for confirmation to move the order back for re-consolidation. On confirmation, the system updates status to In Consolidation once the item is placed at an empty consolidation location.

-

Original order already marked for Re-consolidation: Place item at any consolidation location; re-consolidation continues there.

B) Non-serialized item

- Scanning shows the item is not part of the current order. Take it to the consolidation area.

- If an eligible order in Consolidation can consume it, the app prompts to place it in that order’s bin; otherwise, it shows "No eligible order found".

Technical details

- Scope: Partial non-segregated picking.

- Actors: Packer, Runner/Floor Manager, Item Consolidation operator (Hub Ops app).

- Item types: Serialized (exact order traceability) vs. Non-serialized (eligibility-based matching).

- Baseline: Standard consolidation flow unchanged; reconsolidation activates only upon discrepancy.