From Chaos to Clarity: The Power of Real-Time Visibility in the Supply Chain

Table of Contents

From Chaos to Clarity: The Power of Real-Time Visibility

TL;DR

Real-time visibility turns fragmented supply chains into a calm, coordinated control tower.

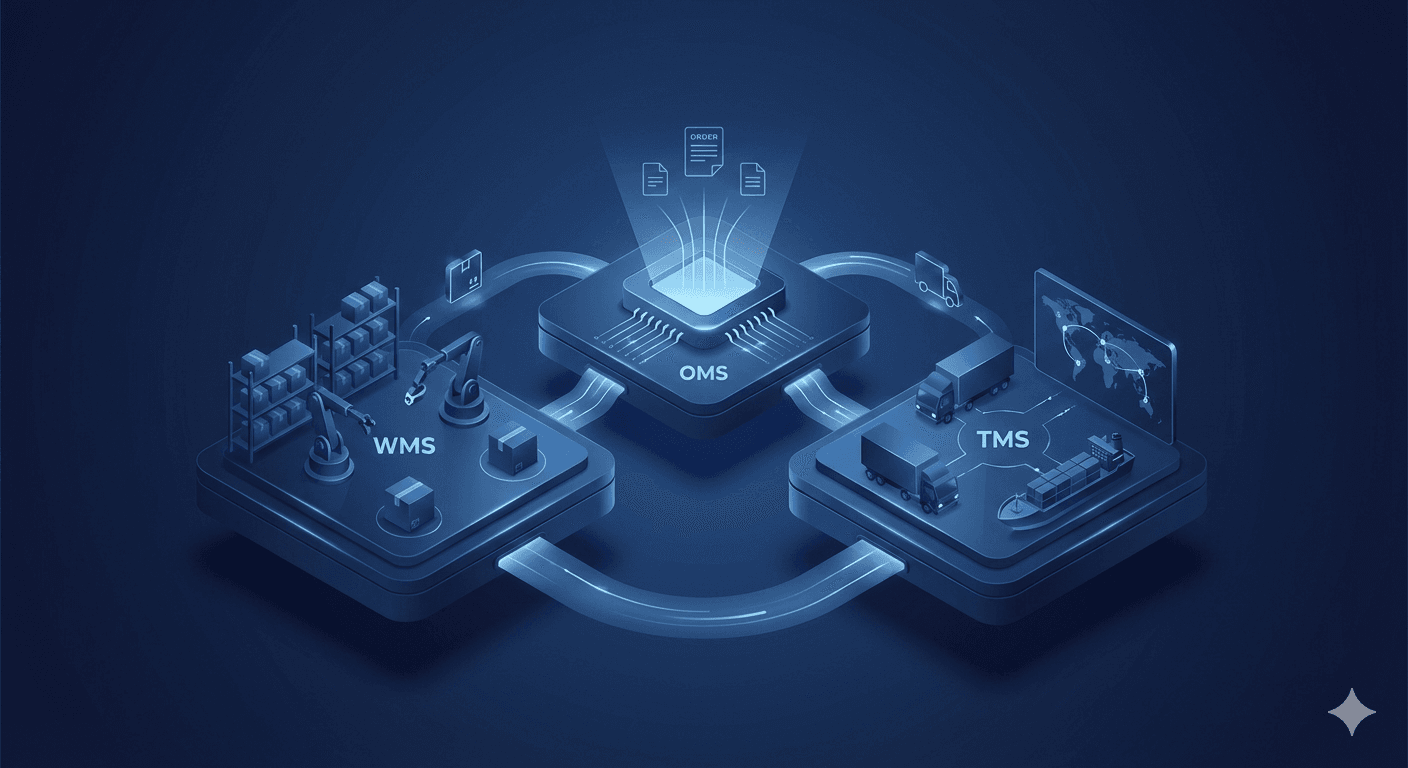

An order management system supply chain view connects orders, inventory, and fulfilment decisions.

OMS decides what should happen, while WMS and TMS execute how it happens.

Visibility across ATP, promise dates, and exceptions reduces surprises and missed commitments.

The goal is not more data. The goal is faster, better decisions.

Introduction: Why Visibility Changes Everything

Picture a busy airport.

Planes land and take off every minute. Weather changes. Gates fill up. Delays happen. Yet most flights move safely because there is a control tower. It does not fly the planes. It sees the whole picture. It decides.

Now, picture a supply chain without that view.

Orders arrive from many channels. Inventory updates lag. Deliveries slip. Returns pile up. Teams react late and argue about facts.

This is chaos.

Real-time visibility is what brings clarity.

In modern operations, that visibility often comes from the order management system supply chain layer. This layer acts as the control tower. It connects orders, inventory, and fulfilment decisions in one place and provides a single source of truth.

This article explains what real-time visibility really means, where an OMS fits, and where it stops.

What an OMS Controls in the Supply Chain

Teams often ask, what is order management in supply chain?

An Order Management System governs the order lifecycle in SCM. It focuses on decisions, not physical execution.

Order Capture

The OMS receives orders from multiple channels:

- Ecommerce storefronts

- Marketplaces

- B2B portals

- POS systems

It normalises them into a single structure. This is the first step toward clarity.

Order Validation

Before an order moves, the OMS validates it.

Common checks include:

- Payment confirmation

- Address validation

- Policy and eligibility rules

Early validation prevents downstream failures.

Inventory Allocation

The OMS decides where inventory should come from.

It evaluates inventory availability across warehouses and stores and applies fulfilment node selection rules.

This decision shapes cost, speed, and customer experience.

Fulfilment Orchestration

The OMS plans how the order will be fulfilled.

Examples include:

- Single shipment vs split shipment

- Warehouse fulfilment vs store fulfilment

- Same-day vs next-day execution

Good orchestration keeps promises realistic.

Exception Handling

Reality is messy.

Stockouts happen. Carriers delay. Customers change their minds.

The OMS manages exception workflows so teams act early, not after failure.

In short, the OMS controls the decisions that define outcomes.

What an OMS Does Not Control

Clarity also comes from understanding boundaries.

An OMS is not designed to manage execution details.

Warehouse Execution Details

The OMS does not:

- Direct workers to specific shelves

- Manage packing stations

- Schedule warehouse labour

These responsibilities belong to a Warehouse Management System.

Transportation Execution

The OMS does not:

- Optimise truck routes

- Dispatch drivers

- Track vehicle sensors

These tasks belong to a Transportation Management System and fleet tools.

Think of the OMS as the planner and coordinator. WMS and TMS are the doers.

When these roles are blurred, systems become heavy and visibility drops.

OMS vs WMS vs TMS

This comparison removes most confusion.

OMS

Purpose Order decisions and coordination

Example Decide to ship from Store A instead of Warehouse B to meet the promise date.

WMS

Purpose Warehouse execution

Example Pick, pack, and stage the order once it arrives at the warehouse or store.

TMS

Purpose Transportation planning and execution

Example Choose the carrier, plan routes, and track delivery milestones.

Each system has visibility, but only the OMS sees the full order lifecycle in SCM from click to return.

Key Workflows Where OMS Visibility Matters Most

Real-time visibility matters most at decision points.

These workflows define customer experience and operational cost.

ATP (Available to Promise)

ATP answers one question: can we sell this now?

The OMS calculates ATP using inventory availability and lead times.

Accurate ATP prevents overselling and backorders.

Promise Date Management

The promise date is the customer’s expectation.

The OMS sets it. If it is wrong, no amount of tracking can fix it later.

Backorders

When stock is unavailable, the OMS decides what happens next.

Options include delay, split, or cancel. Each has cost and service impact.

Split Shipments

Splitting orders can save a sale but add complexity.

The OMS decides when splitting is worth it.

Cancellations

Early cancellations save effort.

Late cancellations waste picks and delivery trips.

OMS rules define this window.

Returns Initiation

Returns start in the OMS.

Early visibility enables smarter routing and faster recovery.

These workflows are where chaos turns into clarity.

Mini Scenario: From Order to Delivery

An order is placed online at noon.

The OMS captures the order.

It checks ATP. The warehouse is out of stock. A nearby store has inventory.

The OMS allocates fulfilment to the store.

It sets a next-day promise date.

The WMS at the store handles picking and packing.

The TMS assigns a carrier and tracks shipment milestones.

The customer receives the order on time.

This works because the OMS had real-time visibility into inventory and clear rules to act on it.

Common Mistakes Teams Make

Even with modern systems, teams fall into common traps.

Using OMS Like a WMS

Picking and bin logic is pushed into the OMS.

The system becomes slow and complex. Visibility suffers.

Missing Exception Management

Dashboards stay green until it is too late.

Without structured exception workflows, teams react after failure.

Ignoring Inventory Latency

Inventory updates arrive late.

The OMS allocates stock that no longer exists, breaking promises.

Chasing Data Instead of Decisions

More reports are added.

Fewer actions are taken.

Visibility without decision-making becomes noise.

What to Look for When Choosing an OMS

Not all OMS platforms support true real-time visibility.

Core Capabilities

- Real-time or near-real-time ATP

- Flexible fulfilment node selection

- Configurable promise date logic

Integration Readiness

- Clean APIs with WMS and TMS

- Event-based updates, not only batch

- Support for inventory latency handling

Exception Workflows

- Alerts tied to business impact

- Clear ownership of exceptions

- Easy rule adjustments

Reporting and Analytics

- End-to-end order lifecycle visibility

- Allocation decisions versus outcomes

- Backorder and cancellation trends

Visibility must lead to action.

Control Tower Cheat Sheet

Controls

- Order capture and validation

- Inventory allocation

- Promise dates

- Returns initiation

Coordinates

- Warehouses through WMS

- Carriers through TMS

- Stores as fulfilment nodes

Doesn’t Do

- Picking and packing

- Route-level dispatch

- Vehicle tracking

Five Metrics to Watch

- ATP accuracy

- Promise date adherence

- Backorder rate

- Split shipment frequency

- Exception resolution time

These metrics show whether clarity is real.

FAQ

What is order management in supply chain?

It governs how orders are captured, validated, allocated, and coordinated across fulfilment and delivery.

Why is real-time visibility important?

It reduces surprises and allows teams to act earlier.

How does OMS enable a control tower?

It connects orders, inventory, and rules into a single source of truth.

OMS vs WMS vs TMS: which gives the best visibility?

OMS provides end-to-end order visibility. WMS and TMS provide deep execution visibility.

Is real-time visibility always truly real time?

Often it is near-real-time. What matters is consistency and trust.

How do exception workflows help?

They surface problems early and assign ownership before failures escalate.

Do I need advanced tracking tools?

Transport tracking tools help with movement visibility. OMS provides the decision context.

Conclusion

Real-time visibility is not about watching everything move.

It is about knowing what to do next.

The order management system supply chain layer provides that clarity. It acts as the control tower. It sees orders, inventory, and commitments together and enables calm, early decisions.

The practical next step is simple.

Map your current order lifecycle in SCM. Identify where visibility breaks. Decide which decisions need to move earlier.

Some teams explore platforms like Omniful for this role. The tool matters less than the mindset.

From chaos to clarity starts with better visibility. And better visibility starts with the right control tower.