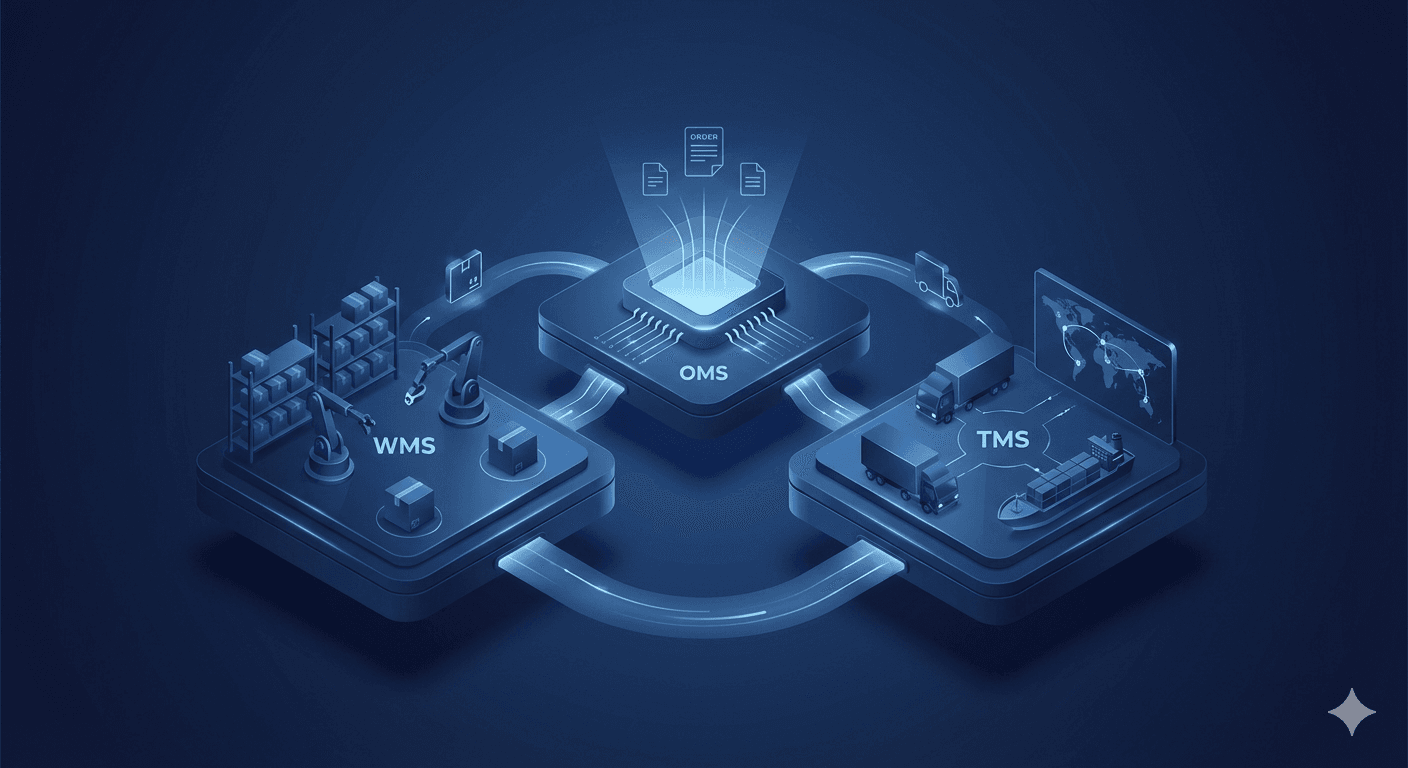

Learn how real-time visibility brings clarity to the order management system supply chain. Understand OMS roles, control tower workflows, OMS vs WMS vs TMS, and the metrics that matter.

Read More7 Min Read

See how modern supply chains use AI and automation to cut costs, reduce emissions, and drive sustainable growth at scale.

Read More5 Min Read

Inventory analysis is the systematic evaluation of a company's stock levels, movements, and management practices.

Read More8 Min Read

Our previous blog about Inventory Analysis covered its definition and importance while exploring different methods and KPIs businesses use for stock optimisation and operational improvement.

Read More8 Min Read

Learn how to reduce picking errors in your warehouse with smarter layouts and real-time scanning tools. Discover MENA-specific strategies and case studies with Omniful WMS.

Read More5 Min Read

Discover how aligning your TMS and warehouse systems ensures inbound freight matches picking schedules, enhancing efficiency and fulfilment speed.

Read More6 Min Read

Bonded warehouses serve as secure storage spaces where goods remain in their original state until import duty and tax payments are due.

Read More7 Min Read

Ever found yourself pondering the difference between Buffer Stock Vs Safety Stock, perhaps even wondering if there really is one? You’re certainly not alone if you have! It’s a common mix-up, and frankly, it happens to the best of us involved in stock management. While they share the goal of operational resilience, their applications, calculations, and strategic responsibilities in inventory forecasting are very different.

Read More8 Min Read

In today’s fast-paced eCommerce, retail, and logistics landscape, businesses need efficient systems to manage orders and inventory seamlessly. Two critical solutions that power these operations are Order Management Systems (OMS) and Inventory Management Systems (IMS).

Read More6 Min Read

Transform your business with Omniful

Where Efficiency Meets Innovation for Unparalleled Success